How custom mesh processing algorithms transformed a medical device manufacturer's inspection workflow

A growing medical device company reached out to us with a familiar problem: their quality control process had become a production bottleneck. Manufacturing titanium implants using metal powder bed fusion, they were spending significant time manually inspecting each part for microscopic deviations that could affect surgical outcomes.

Their process involved scanning each component, overlaying the data against CAD models, and manually reviewing heat maps in standard inspection software. What should have been a quick verification step was taking hours per part, creating delays throughout their production pipeline.

The root issue wasn't equipment failure—it was the inherent nature of metal additive manufacturing, where thermal gradients during printing create predictable patterns of warpage and shrinkage around complex geometries.

Metal powder bed fusion involves selectively melting material layer by layer, creating inevitable thermal stress patterns. These stresses manifest as:

Research consistently shows these aren't equipment problems but fundamental physics challenges that affect even high-end systems.

Traditional inspection software focuses on average deviations and statistical summaries. However, for precision assemblies, the single worst deviation point often determines whether a part passes or fails—and these critical outliers can be hidden within averaged data.

Generic inspection tools also tend to overwhelm operators with information, requiring extensive training and creating opportunities for human error during the review process.

We centered our solution around Hausdorff distance—a computational geometry metric that identifies the maximum deviation between two surfaces. Unlike averaged measurements, this approach provides a "worst-case guarantee" that directly correlates with assembly fit issues.

Directed Hausdorff analysis goes further, distinguishing between material additions (bulges) and material losses (depressions), providing insights into the underlying failure mechanisms.

Our custom solution integrated several key components:

Adaptive Sampling Strategy: Rather than analyzing every mesh triangle, we developed smart sampling algorithms that concentrate measurement points where deviations are most likely to occur, significantly reducing computational requirements while maintaining accuracy.

Optimized Spatial Queries: We implemented high-performance data structures that enable rapid nearest-neighbor searches, even for meshes containing millions of elements.

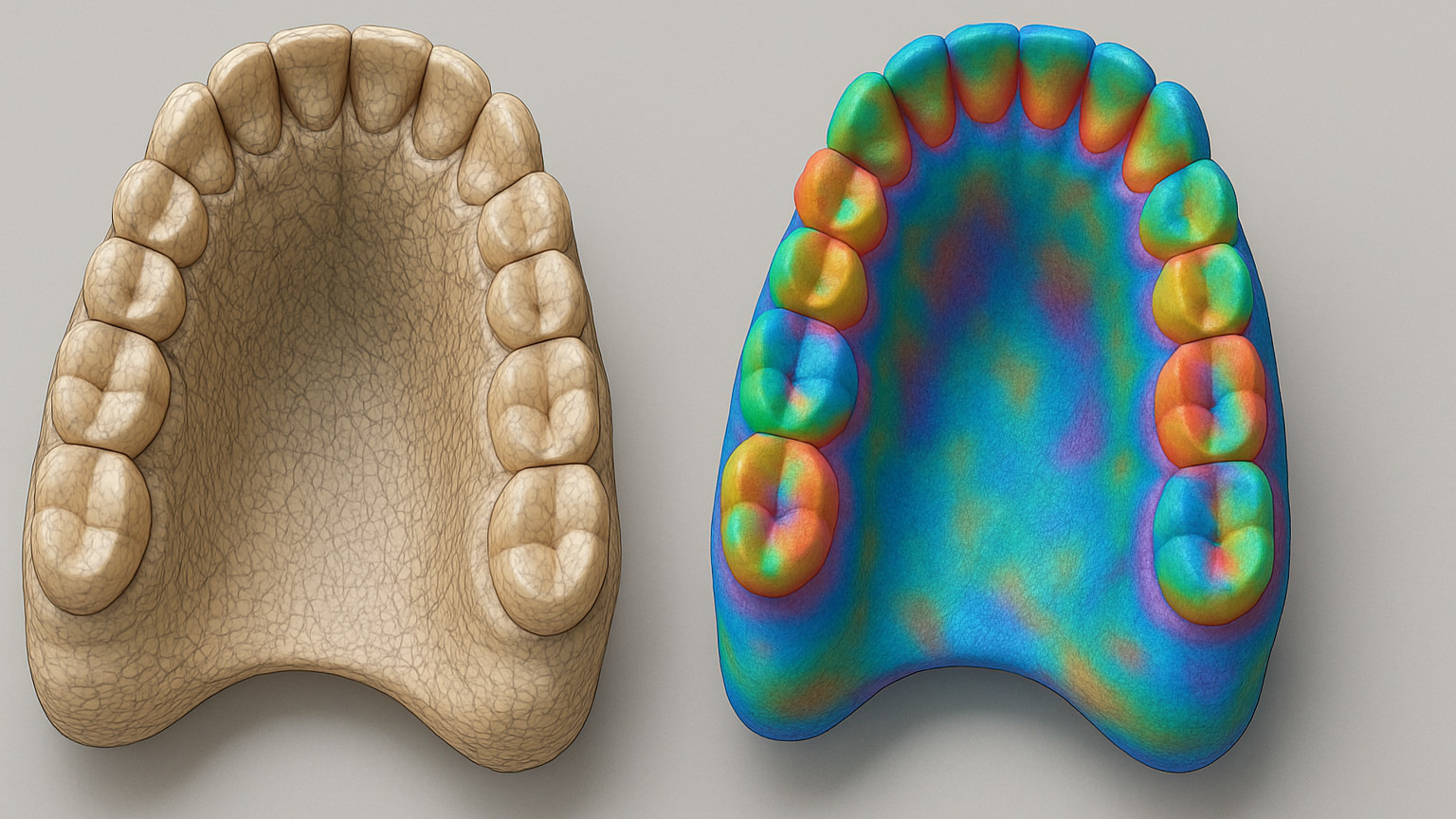

Intuitive Visualization: Results are presented through color-coded overlays that allow operators to make pass/fail decisions at a glance, eliminating the need to interpret complex data tables or navigate through multiple software screens.

Process Analytics: Background algorithms track patterns in the inspection data, building a knowledge base that can identify systematic issues before they impact multiple parts.

The implementation delivered substantial improvements across multiple metrics.

Within the first week of deployment, the system's pattern recognition identified a subtle trend in the defect data that correlated with build position. This led to the discovery of a gradually degrading optical component that had been affecting print quality for months. The early identification prevented numerous potential failures and demonstrated the value of systematic data analysis.

Aerospace Manufacturing: Complex bracket geometries with tight tolerances where traditional coordinate measuring machines are too slow or can't capture organic shapes effectively.

Automotive Prototyping: Rapid validation of components where thermal expansion creates unpredictable geometries, requiring flexible inspection approaches that work directly.

Consumer Electronics: High-volume production environments where precision plastic housings need inspection speeds that match manufacturing rates.

Research Institutions: Academic and industrial R&D facilities developing new materials and processes, where fast feedback loops accelerate development cycles.

Rather than selling software packages, we engineer tailored solutions. Each project begins with understanding your specific parts, tolerances, and failure modes. We then design custom algorithms optimized for your exact requirements.

Typical Engagement Process:

Example Customizations:

Advanced Geometry Processing:

User-Centered Design:

Performance Optimization:

If quality control constraints are limiting your production capacity, we'd welcome the opportunity to discuss your specific situation:

About Elf.3D: We specialize in computational geometry solutions that address complex 3D measurement and analysis challenges. Our work spans from innovative startups to established manufacturers, each requiring unique approaches to geometric data processing.